Achieving practical transformation through the implementation of process improvement techniques is crucial for enhancing, optimizing operations, and achieving operation excellence to deliver tangible outcomes.

If your organization is facing operational challenges, there exists an opportunity to enhance process improvement and efficiency:

LiB’s approach to labor optimization centers around solving issues within impactful processes that involve a significant amount of labor. By conducting thorough analyses of frontline issues, LiB identifies the appropriate strategies and tools to address challenges at each point in the organization, with the ultimate goal of achieving realistic results.

Indirect labor optimization aims to improve and address issues within various support functions that may often be overlooked during improvement initiatives. This approach helps minimize unnecessary labor usage, leading to an overall reduction in the workforce for the company. Consequently, this approach yields better results compared to solely optimizing production processes.

Food manufacturing

One of the company’s main challenges is its heavy reliance on a large workforce in its production process. This has led to the presence of non-value-added labor in various areas of the company. For example, the company has employees who are engaged in repetitive tasks, production lines that experience frequent interruptions, and even the production of products that do not contribute to the company’s profit without its awareness. Therefore, it is necessary to expedite the development of the production process to enhance efficiency and effectively utilize production resources.

During the quick win phase of the project, we were able to reduce labor utilization by more than 37% while maintaining the same level of production quality. Additionally, there is no need for further investment in production line improvements. When considering the entire project plan, we anticipate annual savings of over 24 million baht.

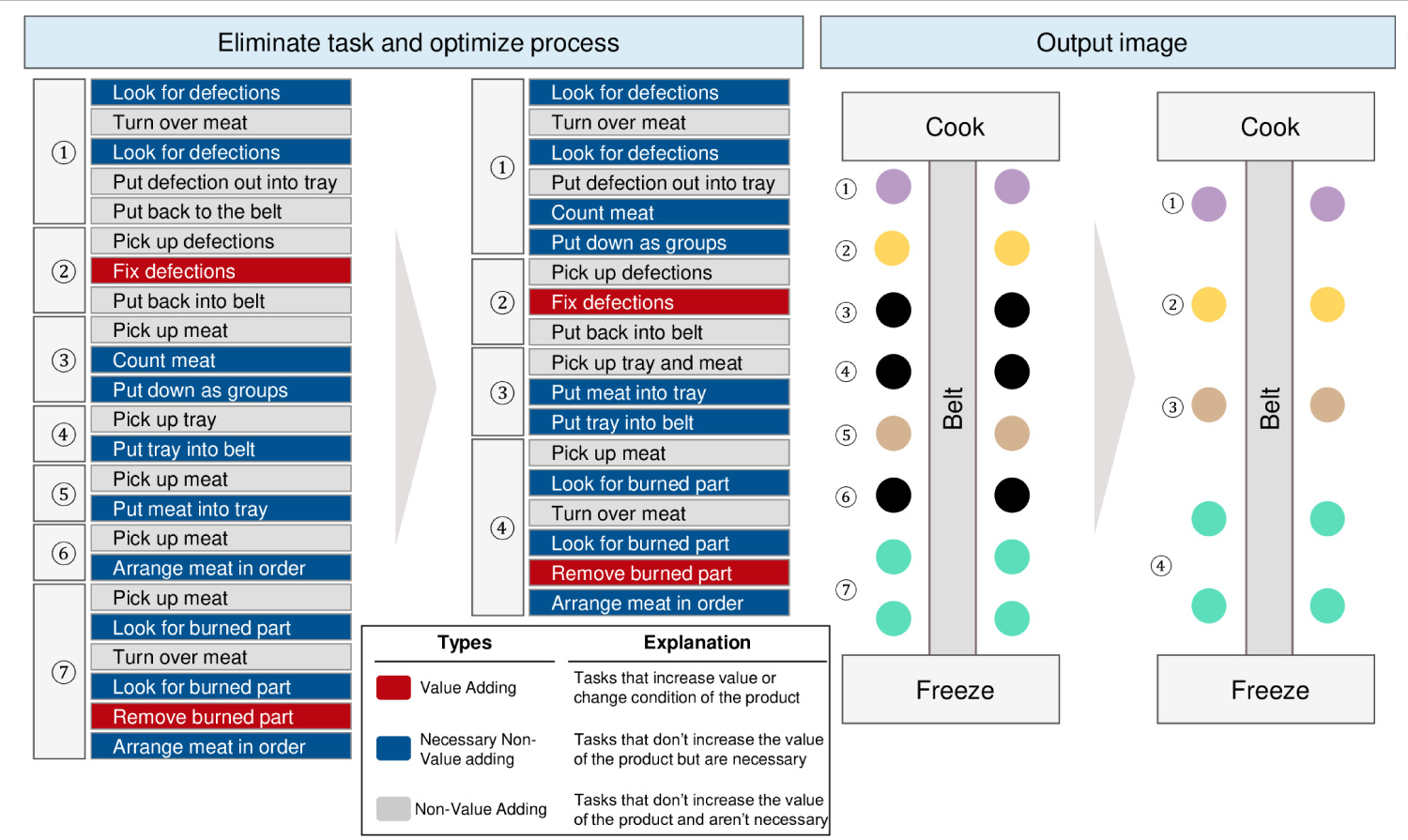

Their main production process relied heavily on a large workforce. LiB conducted a thorough analysis and identified areas within the production process where non-value-added activities were present. These included unnecessary job movements or redundant inspection tasks, leading to excessive labor usage. LiB was entrusted with facilitating the improvement of the production process to enhance efficiency and ensure cost-effective resource utilization.

LiB’s approach consisted of three main steps. First, we meticulously analyzed and eliminated any unnecessary activities from the production process, ensuring that these eliminations did not impact other areas or necessitate modifications to the production process itself. For instance, we successfully eliminated redundant inspection tasks without compromising other production activities. Second, we focused on designing a more efficient production process by exploring new methods to enhance production efficiency. This involved the creation of tools that visualized the sizes of items, aiding in quicker sorting and incorporating suitable technology for process automation. During this process, the focus was on ensuring the cost-effectiveness of these investments. We developed detailed implementation plans and continuous improvement strategies to meet project timelines. Finally, we employed a specially designed optimization program to analyze the optimal workforce required at each point in accordance with the production plan.

As a result of LiB’s interventions, one of the quick win examples successfully achieved a remarkable reduction in labor utilization. The number of employees required was reduced from 16 to a mere 10, resulting in a reduction of over 37%, without compromising the production quality. Moreover, no additional investment costs were incurred to improve the production line. When considering the entire project, the expected annual savings amount to over 24 million baht.

Thank you for your interest.

Please fill in some important information and we will be in touch.