Unlocking the Journey to Smart Factory

Uncover solutions to overcome limitations and add business value to Thai manufacturers.

The concept of a Smart Factory refers to an integration of business strategies, cutting-edge technologies, and an adept workforce to cultivate adaptable capabilities that yield sustainable returns on investment while prioritising environmental sustainability. We witness a distinct shift towards the era of Smart Factories, notably within key industries like automotive manufacturing, the food industry, electronics equipment manufacturing, and beyond.

However, not every entrepreneur can smoothly transition to developing a Smart Factory, as they often encounter numerous challenges at the outset. These hurdles might revolve around uncertainties regarding the absence of clear strategies or uncertainty about where to begin.

In light of this, LiB Consulting, a leading management consulting firm based in Japan, renowned for its expertise in corporate strategy and transforming manufacturing industries into Smart Factories, has meticulously examined the underlying catalysts. They aim to assist entrepreneurs in gaining a fundamental understanding of the Mega Trends that undeniably shape every industry globally. It is crucial to grasp the three primary external factors, namely:

- Technological factors: The changing consumer demands have evolved into an On-Demand economy system to meet instantaneous needs. This convenience has introduced complexities into the supply chain, as consumers globally can order products and services 24/7. This poses a challenge for every industry to adapt their strategies quickly to evolving consumer behaviours.

- Political and environmental factors: Environmental policies, particularly green economy policies and the goal of achieving Net Zero Emissions, have become urgent priorities. This has compelled businesses to adapt and demonstrate responsibility towards the planet. Businesses have done so through various approaches, such as creating strategies for reducing energy consumption, utilising technology in production processes and warehousing, and choosing clean energy sources. Companies that meet environmental standards often have good export figures because their practice adds value to their products.

- Societal factors: Societal factors are challenging to control. For instance, when governments increase the minimum wage to improve the quality of life for workers, it also burdens businesses with higher costs. Consequently, it pushes businesses towards developing Smart Factories to maintain business balance while eliminating limitations in efficiency and effectiveness throughout the supply chain, from production to delivering products to consumers.

Understanding the Core Objectives of Smart Factories

LiB Consulting has analysed and presented objectives to enable organisations to transform into Smart Factories effectively and efficiently. There are four key results businesses should aim to achieve when transforming into a Smart Factory, namely:

- Operational Efficiency Improvement: Achieve operational efficiency by integrating knowledge from best practices and technology, especially within the context of the supply chain. This enables continuous improvement of processes throughout the production chain. For instance, utilising Radio Frequency Identification (RFID) technology to monitor inventory status in real-time allows business owners to improve decision-making processes during production and streamline complex workflows.

- Quality Enhancement: Enhancing quality involves consistently controlling product standards to meet customer satisfaction. This includes metrics like aiming for Zero Defects, monitoring defects per unit, and measuring Overall Equipment Effectiveness (OEE) through sensor installation. These sensors connect machine status data, offering real-time feedback on abnormalities to stakeholders or even halting production automatically upon detecting severe issues.

- Cost Optimization: Adapting to changes in business variables is inevitable and affects operations. This includes changes in operation plans, fluctuations in raw material prices, or even production capacity. Advanced technology aids in creating data products that are used for analysis to reduce expenses in line with changing circumstances. For example, production plans can be instantly adapted based on changing parameters through the use of Machine Learning to analyse production scenarios for maximum output under minimal costs.

- Market Responsiveness: Market responsiveness involves tailoring products and services to meet customer demands, enabling quick penetration of new products or services into the market and leading to shorter payback periods for entrepreneurs. Many organisations seize this opportunity by implementing tools such as Product Lifecycle Management for product design, development, and supply chain integration to improve alignment between product design and manufacturing.

Progressing towards developing Smart Factories that meet business needs

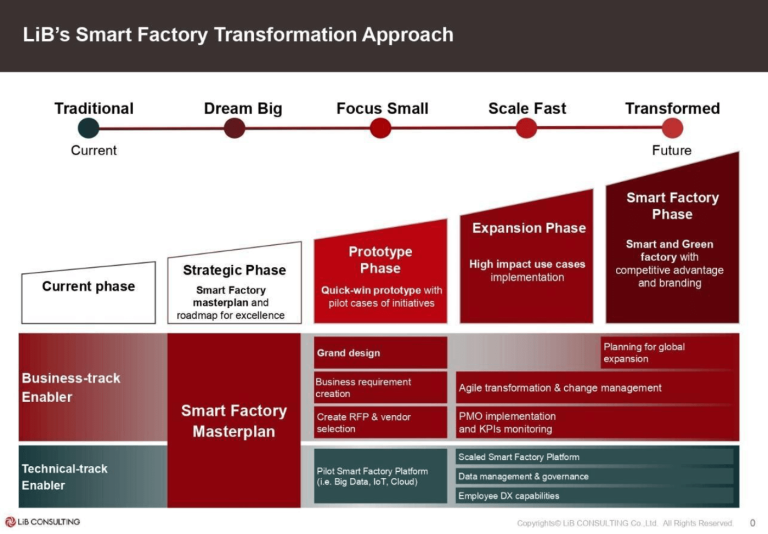

The development of Smart Factories involves applying necessary technologies to align with the industry context. This development can be divided into three main steps, also referred to as the three ‘S’s:

- Strategy Formulation: Successful strategy formulation requires three main components: Transformation aspiration, which involves creating a roadmap with defined goals and success metrics, such as Key Performance Indicators (KPIs) or Objective Key Results (OKRs); Transformation strategy, which involves defining scopes of change (where-to-transform) and methods of change (how-to-transform), including selecting necessary technologies—for example, utilising tagging technology for efficient inventory tracking and dashboard visualisation to adjust production and delivery plans in real-time in the scope of the supply chain unit; and Transformation capability, considering necessary capabilities in personnel, processes, technology, data, and policies.

- Sequence: The transition towards creating a Smart Factory is a higher-level goal that requires integrating short-term and long-term plans. This strategic sequence enables businesses to initiate small changes, which could lead to remarkable effectiveness—for instance, beginning with trials to integrate supply chain data into a central hub and presenting it on a dashboard for immediate production and delivery planning adjustments. Once short-term plans are successfully executed, progression to other operations to achieve ultimate goals from the roadmap becomes feasible.

- Structure: This involves reshaping teams to take responsibility for implementing plans into reality. This factor mostly revolves around four key job positions: Product Owners, Business Experts, Technology Experts, and Data Experts. Notably, Smart Factories don’t focus solely on reducing personnel and replacing them with technology. Instead, there are instances in which organisations may need to retrain their staff to deploy the technologies.

The shift toward Smart Factories is now a pressing priority for the manufacturing sector to sustain global competitiveness. Finding the right partner to support your journey on initiating and implementing transformation could be a key towards successful revolution.

LiB Consulting, renowned consultants for numerous factory businesses in Japan and trusted by leading global companies, recognises the significance of advising organisations through this transition to maintain their competitive edge. We provide tailored business strategies to fulfil the diverse needs of the manufacturing industry, thereby contributing to the ongoing growth of Thailand’s manufacturing sector as a valuable industry partner.

About LiB Consulting (Thailand)

Established in Tokyo, Japan, LiB Consulting is a leading management consulting firm committed to delivering results-driven solutions and practical implementation strategies. Our core mission is to increase companies that shape a better world in the next century. Specialising in consultancy services for both companies and government agencies, we offer comprehensive support ranging from strategic development to implementation enhancements. At LiB Consulting, we firmly believe in the transformative power of consultancy to drive positive change and facilitate the growth of organisations that add significant value to society.

For more information, please contact

LiB Consulting Thailand

Email: info_thai@libcon.co.jp

Phone: +66 2-104-9153

LiB Consulting Smart Factory Team

Dr. Lalita Haritaipan (Min)

Email: lalita_h@libcon.co.jp

Maitree Tanungkunanij

Email: maitree_t@libcon.co.jp