Effective supply chain management requires a balance of key systems, such as manpower planning, inventory management, logistic optimization, careful site selection, and more, to streamline the value chain and drive efficiency in every stage of the supply chain

If your organization is grappling with operational challenges, it’s a clear indication LiB’s Supply Chain Management program can further enhance efficiency:

Our expertise lies in strategically planning and restructuring your workforce to ensure optimal staff levels align with production plans. By analyzing appropriate staffing requirements, we can effectively optimize your workforce resources, resulting in maximum efficiency.

We excel in planning for efficient inventory management, aiming to minimize stock levels, reduce costs associated with inventory, and enhance customer satisfaction.

Through our dynamic route optimization, we offer logistic optimization solutions that significantly improve supply chain efficiency and implement smart routing strategies.

Leveraging location allocation and network analysis techniques, we assist in making informed decisions regarding site selection to ensure the smartest facility placement.

Banking

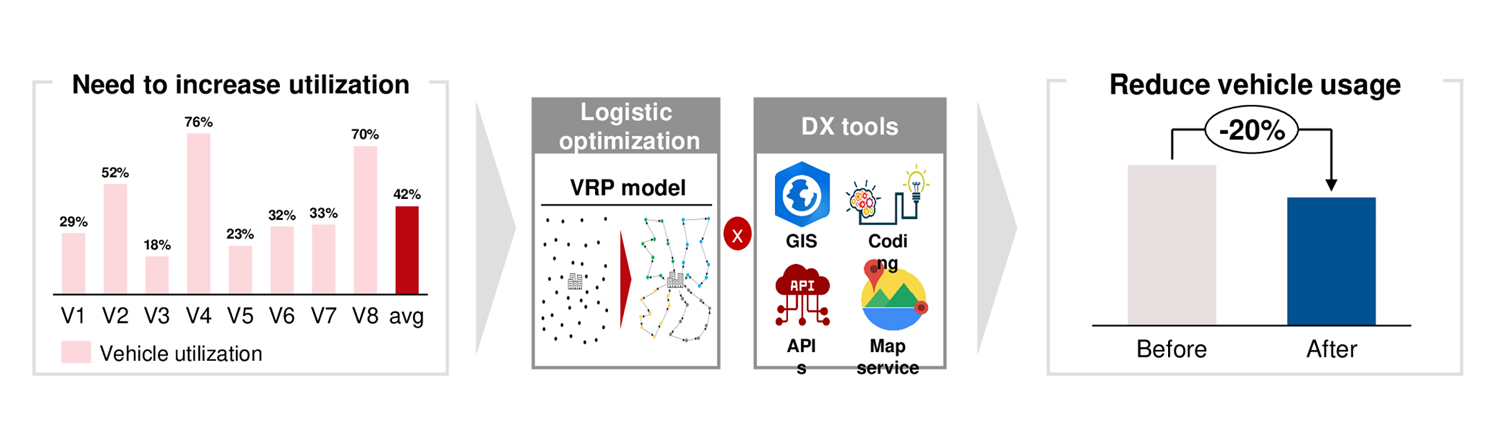

The company is facing a supply chain problem, with increased transportation costs due to an inadequate number of vehicles that fail to align with the actual workload. This has led to unnecessary personnel costs. Urgent measures must be taken to improve processes and curtail costs in this area.

The company successfully reduced the number of vehicles from 324 to just 257, representing a substantial 21% reduction in the total fleet. This amounts to potential savings of over 90 million baht per year.

The company encountered challenges in increasing transportation costs due to various factors, including an excess of vehicles and drivers compared to the actual workload. Additionally, there was a notable absence of efficient route planning management. Collectively, these factors led to unnecessarily high transportation costs. Prior to implementing improvements, the company operated with a fleet of 324 vehicles, incurring significant management costs of 460 million baht annually.

To address these challenges and achieve optimal transportation management with the fewest possible vehicles, the company executed a two-phase plan. The first phase was implemented in the Bangkok metropolitan area, where a quick-win strategy was utilized. This strategy had a significant impact, resulting in the reduction of 58 vehicles or 18% of the total fleet (high impact). The second phase covered regional areas. Both phases consisted of three main steps:

Of these steps, the second proved to be crucial, as it required the employment of an optimization tool to design new routes that minimized the number of vehicles needed while accurately reflecting real-time running conditions on-site. These conditions included actual distances, the time spent on the road, and maximum vehicle capacity.

During the first phase, conducted in the Bangkok metropolitan area and its suburbs, the results revealed a reduction from the original 58 vehicles to 42, a remarkable 28% decrease. Following the success of the first phase, the second phase covered regional areas using the same process. The outcome demonstrated a reduction from 266 to 215 vehicles, a 19% decrease. The overall project results showed a reduction in the number of vehicles from 324 to 257, representing 21% of the total fleet or potential savings of over 90 million baht per year.

Thank you for your interest.

Please fill in some important information and we will be in touch.